PORTRAIT OF RESTORED DROP BOTTOM GONDOLA 871

.

.

The OLD very deteriorated interior, compared with the NEW interior with all new wood and bolts, repaired brackets, and wood sealed for protection.

The OLD car had more modern lettering on the old car spreads “D&RGW” above two sets of doors, compared with the NEW lettering of the late 1920s, which keeps “D&RGW” above a single door, i.e., between only two straps.

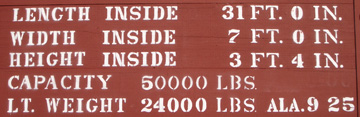

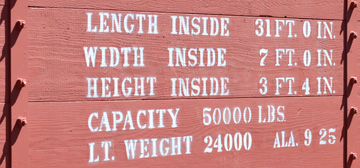

The OLD car used abbreviations for dimensions and included the “flying” Rio Grande at top right, compared with the NEW lettering that uses full words for dimensions and has no “flying” Rio Grande.

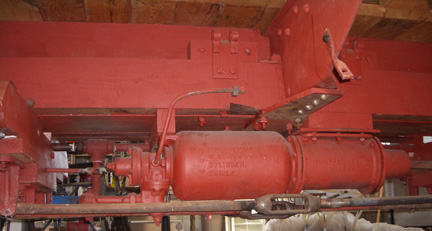

On the OLD car bolts were loose and the brake cylinder hung down, compared to the NEW car withnewwood and bolts, which keep the brake cylinder solidly in place.

Summer 2009 – Major Disassembly

May 2009. Dennis D’Alessandro cuts through one bolt, and Ashley Malcolm punches another one out. Eric Mencis

May 2009. Eric Mencis chisels a bolt, and Jim Granflaten torches off one. Photo of Jim by Eric Mencis

June 12, 2009. Trying to remove an old bolt with a wrench didn’t work many times. The long thick wood members are floor timbers for nailing down the center floor boards. The rotted imbers had to be dug out. Tim Bristow

July 3, 2009. Beams along the center steel channels were rotted and structurally unfit for reuse. All were being replaced. The single long bolt standing above the left steel sill once held a floor timber above it. The three bolts at center, next to the left steel sill, would normally attach to the brake cylinder mounting plate. The two bolts and hole for a third bolt in the right steel sill also attach to the brake cylinder mounting plate. The rotted wood around the left three bolts obviously provided no support for brake action. Tim Bristow

Many bolts were rusted away to a fraction of their original shank diameter, and many mounting plates were badly corroded to thin, structurally unsound pieces. The four rods shown in the photo are ends to the truss rods, also thinned by corrosion. Most bolts and many mounting plates would be replaced. Tim Bristow (top) and Dennis D’Alessandro (bottom)

July 10, 2009. One end of the gondola with the body completely removed. The metal arch above the center sills is part of the body bolster (supporting cross member) attached to the frame. It has a center pin that fits into the truck bolster. The brake hand wheel and rod leaning against the end sill attaches to the endwall. Tim Bristow

Restoring Drop Bottom Gondola 871: 2009–12

Photos by George Niederauer unless otherwise noted.

October 6, 2009. The frame is at its barest, cleanest, and brightest – only two longitudinal center channel sills and their end sills. Still attached are the couplers and draft gear. Before painting with primer they were sandblasted and inspected for defects. Couplers are not painted, per FRA regulation – better to see fractures.

November 3, 2009. Hank Pantzar chisels a notch to fit the beam around a metal part of the channel freame. The holes were drilled to fit over rivet heads.

November 3, 2009. Tom Bristow (far left), Chris Killgore, Ted Parks, and Hank Pantzar, all of Pagosas Springs. Dennis D’Alessandro was out of the camera range. They are testing the fit of a sill into a channel. The wood center sills are 31.5 feet long, 8 inches high and 4 inches wide – each is one solid piece of fir.

November 3, 2009. Ted Parks and Chris Killgore paint a sill with a water sealer such as used on house decks.

2009 (top) and October 1, 2010 (bottom). A cross member before and after restoration. Dennis D’Alessandro

October 1, 2010. Tom Artzberger operates a drill while Chris Killgore steadies the cross member. They are drilling mounting holes in lateral beam mounting plates, which will be riveted to the cross beam. Dennis D’Alessandro

October 1, 2010. Test mounting an oak wood insert and metal brake rigging parts to the back side of an end sill, The wood would be sealed and the hardware would be primed with red oxide before permanent mounting. Dennis D’Alessandro

October 15, 2010. The restored air reservoir and brake cylinder are mounted under the center sills. A new steel mounting plate and wood spacer provide a solid mount to support action by the brake cylinder. Dennis D’Alessandro

October 15, 2010. Tim Bristow bolts a cross member to the sills. Dennis D’Alessandro

October 15, 2010. The full metal skeleton of the frame is back together, fully restored – structurally sound to take a full load again.

October 29, 2010. After the skeleton frame was finished, the crew moved on to disassemble the trucks. Here theB end truck has been disassembled, and top bar of a frame on the A end truck has been removed. Dennis D’Alessandro

October 29, 2010. Parts from disassembled truck B are scattered around. Dennis D’Alessandro

Where the sides step down, fractures have formed on the bottom of a spring seat. Dennis D’Alessandro

Mark Smeltzer is painting a spring seat (upside down). Dennis D’Alessandro

November 1, 2010. Some nuts take a large “cheater pipe” to provide enough leverage, as Keith D’Alessandro (Dennis’ son) discovered, as he removed the last bolster retaining bolt. Dennis D’Alessandro

November 1, 2010. The wheel sets after the trucks were disassembled. Dennis D’Alessandro

2011 – Major Restoration Continues

April 30, 2011. All center sills have been coated with preservative and mounted on the metal frame.

April 30, 2011.It is too expensive to get a field riveting machine to our work site or to take the frame to a shop for riveting. Our volunteers came up with a creative solution. They made special bolts with round heads that look like rivets, then welded the bottom nuts after tightening them. Lastly, they ground down the built up weld to make the welded nuts and bolts look like rivet heads, too.

June 4, 2011. Nearly all floor timbers are in place, bolted to the center sills. The inverted-V shaped structure in the foreground is the body bolster. Pictured are Jay Scherer and Dennis D’Alessandro.

July 23, 2011. Closeup of body bolster. A truss rod will fit over the saddle on top.

July 23, 2011. All floor timbers in place, strap hinges for drop doors temporarily pinned in place for priming,door boards being sealed.

July 23, 2011. Close up of two door strap hinges and their mounting blocks.

July 23, 2011. Both trucks nearly completely assembled.

September 8, 2011. The middle eight doors are mounted. The four end doors require special attention to an additional bracket for the winding shaft mechanism.

October 8, 2011: Both fully restored trucks are in place, centered on king pins projecting down from the body bolsters through the center plates on the truck bolsters. Brake gear is shown in front of the truck.

November 25, 2011. The gondola trucks and frame are moved from our tent to a spot inside a heated airplane hanger with a smooth floor. The gondola sits on a wood 2×4 track on top of two layers of the old side planks from the gondola to spread the load and protect the solar heating in the floor. Our thanks go to Doug Lashley for the use of such a luxuriant work space.

2012 – Restoration Completed

March 17, 2012. Ron Nott and Jonathan Smith, our oldest and youngest volunteers, put leverage on a stubborn bolt to free up the brake shaft chain sheave.

March 31, 2012. View from B (brake) end. All four corner posts are bolted to side sills and bottom end boards with the associated corner hardware: sill steps and winding shaft lever mechanism. All four winding shafts and their large levers are in place. The doors were removed and stacked at the end to allow working space within the frame.

April 3, 2012. Rusty Barnes heats a thick truss rod to bend it lower to clear a door hinge. Just one of many – so many – such tasks.

April 12, 2012. The corner of the A end is finished except for torching off the bolt ends to lock the nuts. Note the bare strap with the hand holds bolted through it. The vertical 2×4 holds the frame level. Duane Danielson

April 12, 2012. Ron Nott uses a portable crane to lift one of the heavy side boards, while Tom Artzberger and Dennis (out of picture at right) are ready to guide it into position. Duane Danielson

April 25, 2012. The center floor is half spiked down, while Dennis D’Alessandro works on an extension to an end intermediate post. The heads of the floor timber bolts were countersunk and sealed against water with caulking, also making it easy to lay the floor. Historically, many floor planks had to be chiseled to fit over bolt heads.

April 28, 2012. The center floor is complete, nailed down with 40d (5-inch) spikes.

April 28, 2012. Winding shaft lever and pawl. Note that the bolt ends have been torched off, which also locks the nuts in place. Also note that the nuts are aligned square with body, as was done originally as a sign of good craftsmanship.

April 30, 2012. Ground level view of the A truck, showing a brake beam with a pair of brake heads, shoes, and hangers. From the end sill the truss rods run over their saddles on the body bolster and bend down at angle through the cross timber whose ends are door stops.

April 30, 2012. The truss rods bend under the queen posts on the cross timber.

April 30, 2012. The A end truss rod connects with the B end truss rod at the center of the gondola. This side view shows the air brake assembly, with the triple valve attached to the left of the air reservoir and the brake cylinder to its right. The small air pipe above the reservoir will connect from the triple valve to the retainer valve at the Bend of the car, near the brake wheel. Above the end of the small air pipe is one-half of a strap hinge for a drop bottom door.

May 2, 2012. Brake wheel on brake shaft with a bearing attached to the top plank. The shaft sits in the stirrup hanging from the end sill. To the left of the stirrup is the brake shaft chain sheave. A chain will run from the shaft through the sheave to a brake rod. The ends of the bolts have yet to be torched off.

May 27, 2012. Greg Simpson sprays a light coat of white on stencils he made, then hand paints letters.

June 2, 2012. All doors are installed, and their chains are adjusted for good closure. (Photo: Duane Danielson)

June 8, 2012. Moving day. George monitors the door clearance and track one side, while the driver for Knecht’s Towing winches it upon Randy Babcock’s light track laid on Knecht’s roll back trailer. Stefan Niederauer

June 8, 2012. Ron Nott monitors the other side of the track as the rear truck approaches the junction of the wood 2 x 4 rails with the metal rails. Stefan Niederauer

June 8, 2012. The gondola is chained down on the trailer, ready for the trip from the Durango airport to Silverton. The end sign, 8″ CARRIER IRON RIVETED, was placed on cars after their wood center sills were replaced with steel channels during their rebuild in 1926. Stefan Niederauer

June 8, 2012. A group of volunteers photographed on moving day. L to R: George Niederauer, Mark Kasprowicz (Oxford, England), Ron Nott, Duane Danielson, Dennis D’Alessandro. Stefan Niederauer

June 8, 2012. Dennis D’Alessandro operates the gondola brake as necessary to keep the easy rolling gondola from overtaking the Jeep. Ron Nott hitched a ride on the gondola. Stefan Niederauer

June 8, 2012. A vivid illustration of the contrast between the fully restored drop bottom gondola and the deteriorated bare frame of the high side gondola in front of the Silverton Northern engine house. Stefan Niederauer

D&RGW Freight Cars

Durango Railroad Historical Society is comprised of a dedicated group of individuals who are united by their interest in narrow gauge railroading and focus on the preservation of southwest Colorado’s railroad history.

The Durango Railroad Historical Society is a non-profit corporation in Colorado and is a public charity under section 501(c)(3) of the Internal Revenue Code.