Restoring High Side Gondola D&RGW 1400

Photos by George Niederauer unless otherwise credited

Recent Progress – Reverse Chronology

May 15: Gondola moved to Silverton. Some lettering remains to be done.

May 14: Dennis D’Alessandro paints while Duane Danielson (hidden) presses stencil to surface.

May 14: Tom Artzberger works on finishing piping to triple valve.

May 13: Duane Danielson touches up after stenciling.

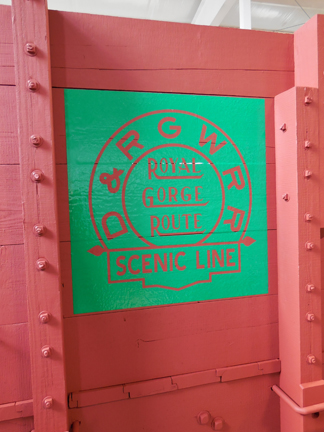

May 8: First stencil – vinyl with sticky backing.

May 6: Gondola painted with top coat.

April 30: Nearly all hardware on B end is installed.

April 16: Duane Danielson and Tony Palmer attach a stake extension.

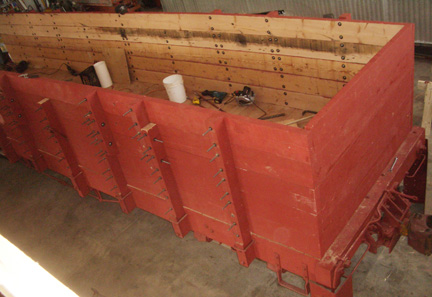

April 16: End board stacked in place on B (brake) end.

April 16: All sides boards are in place and most bolts are installed. Four stake extensions (‘sisters’) are yet to install. Only a few of the excess lengths on the bolts have been cut off.

April 11: Side boards are going up with just enough bolts to hold them in place. The long bolts are torched off, which also locks the nuts in place. Duane Danielson

April 4: We finished installing the floor, including drilling holes for the four side wall braces (long U-bolts). Duane Danielson

March 22: Dennis D’Alessandro paints the frame, stakes, and truck structures with our new low-pressure paint sprayer.

March 15: OUTSIDE VIEW – Details of a stake attached to a sill with a U-bolt and additional bolt with a steel plate. INSIDE VIEW: Nuts on a U-bolt are locked with a piece of hardwood nailed in place between them. The truss rod is unpainted.

February 22: At the end of the day, the crew (Mark, Dennis, Duane, Tony) gathers to discuss the work of the day and for the next work session. The open three-ring binder in the foreground is one of two copies that contains many photos and sketches from our original survey of the gondola and phases of disassembly – our reference book.

February 22: Tony Palmer holds a drilling jig while Mark Kasprowicz drills bolt holes for side boards in a stake.

Restoring High Side Gondola 1400 – From the Beginning

2010 The only work performed on the 1400 in 2010 was taking photos and measurements of its existing condition and acquiring information about this type, including engineering drawings, courtesy of members of the Friends of the C&TS.

2011: Disassemble Body

On March 12, 2011 we began to disassemble the gondola.

March 19, 2011. The A end hardware and end boards were removed on the high side gondola to provide easier access during the disassembly process. These boards are rotted and need to be replaced.

April 30, 2011. Dennis D’Alessandro (standing) punches out a bolt so he and Tom Artzberger (on gondola floor) can remove the bottom board. Nearly every bolt had to be cut or torched off. Even if they came off with a wrench the shank was badly rusted because of moisture held in place by the wood. All bolts will be replaced.

May 5, 2011. Three sides are now off. Removing each side is a tedious process because each rusted nut has to be burned off with a torch – about 154 per long side!

June 4, 2011. Cleaned debris off tops of sills and removed nails (or pounded down remaining stubs). Took detailed photos and measurements of components on outer sill. Note how center and end sills drop from cars being banged together. The sill drop starts at the rear of the draft gear frame.

September 20, 2011. Bare frame on trucks with brake and other undercarriage hardware still in place.

September 20, 2011. A close-up of part of the frame reveals a cross member notched too much at the end, requiring a shim, and notched slightly for the intermediate sill – signs of custom fitting of individual pieces of the frame.

2012: Disassemble Frame and Trucks – Begin Restoration

June 20, 2012. Ron Schlueter is removing a truss rod as Duane Danielson and Dennis D’Alessandro look on. Judy Schlueter

June 20, 2012. The ends of the end sills are cut off to allow removing the outer and intermediate sills in whole (unless they break because of damage). In the view the tenons are in decent shape on the outer sill, but have virtually disintegrated on the intermediate sill. Judy Schlueter

June 27, 2012. The A end suffered one or more collisions that caused the two center sills to buckle and break. They fell apart upon disassembly. A truss rod runs near the top of a center sill, then angles down towards a queen post. The brake pipe runs along below the truss and curves down below the center sills to the air reservoir. A distance block between the center and intermediate sills is visible at extreme left. Judy Schlueter

June 27, 2012. Looking back towards the B end. The two cross frame tie timbers with their queen posts are bolted to the two center sills, with the air brake cylinder and reservoir partly hanging from one center sill. Dave Hibl

June 30, 2012. Body disassembly complete, leaving behind the two trucks.

August 29, 2012. Mark Kasprowicz, Oxford, England, drills main part of mortise on a center sill with a Forstner bit.

August 29, 2012. Duane Danielson, Durango, chisels to square out a mortise in a center sill.

August 29, 2012. Tony Palmer, Durango, chisels to square out a mortise in a center sill.

August 29, 2012. Dennis Busby, Gold Canyon, Arizona, rolls primer on sills. The primer is tinted as abetter backing for the red top coat.

August 31, 2012. All the timbers for the frame are assembled together. The frame is upside down. The sills making up the main frame are mortised and tenoned together tightly. It took pipe clamps to draw the tenons into the mortises. The lower level of timbers are simply laying in place at this time (the short sub sills should be on the center sills, not the intermediate sills). All timbers are new except the eight distance blocks between the center and intermediate sills. The frame assembly team, led by George Niederauer, was (L to R) Ron Nott, Farmington, Tony Palmer, Steve Grothe, Decatur, TX, and Dennis Busby.

September 26, 2012. Two distance blocks (spacers) with primer paint and tie rods between the center and intermediate sills. They are right side up. The vertical bolts in the blocks are for reinforcement. The sills and their bolts are all new, but all distance blocks and their bolts and tie rods are from the old frame. The blocks will be fore and aft of a truck, and brake gear will hang from them.

September 28, 2012. The frame, painted with red top coat, is upside down for ease in bolting down the lower timbers. All timbers along the center sills are bolted in place, except the cross members, which will be drilled and bolted during final assembly. The center sills, only 8.5 inches apart when assembled in the end sills, are moved wide apart to make room for workers.

October 8, 2012. The frame is upside down on metal stands. The restored end sills are primed in pink, as are the spacer boards under the draft gear. Ten bolts vertically and ten bolts horizontally will solidly attach this draft gear assembly to the two center sills and end sill. Also, two truss rods will attach to the draft gear through the end sill. Although not obvious in the photo, the ends of the draft gear extends along the shorter (pink) spacer under the notch in the sub sills.

October 24, 2012. We added the end sill and the second draft gear assembly, on the A end, thanks again to the help of a forklift and operator Brian King from San Juan Timberwrights. Dennis D’Alessandro helps guide the gear into the tight fit between the center sills.

November 21, 2012. The two cross frame tie timbers (needle beams) are installed, along with the short sub sills on either side of them along the center sills. Each needle beam has four queen posts bolted through them and the sills. The air reservoir and brake cylinder are being bolted to the center sill and through a short block on an intermediate sill. At the far end are a body bolster and a draft gear assembly.

November 21, 2012. At the near end a body bolster is in place, intertwined with draft gear frame. Four 1×24- inch bolts tie the two together with the center sills – the largest bolts on the gondola.

November 24, 2012. New and old U-bolts for posts (stakes). Note the deterioration next to the threads, where the bolts sat inside a wood sill.

November 24, 2012. Old and new long U-bolts for side wall braces. The old ones were bent up from loads being dumped on them.

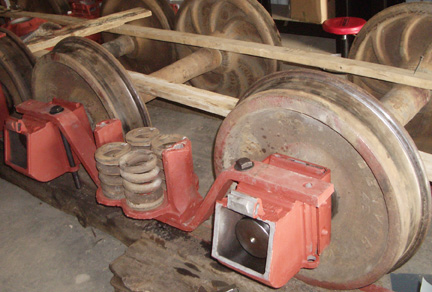

November 30, 2012. One truck assembly is essentially completed, except for a cover, journal pads, and journal oil. The 2x4s are used as tracks when the trucks are hauled on a trailer.

November 30, 2012. The other truck is in the process of final assembly and was completed later in the day.

November 30, 2012. Dennis D’Alessandro works on a journal box and its oak seal to make a good fit in the slot at the back of the journal box.

December 1, 2012. The four truss rods and the remaining frame bolts are in place, completing the work on the frame and its major hardware.

December 5, 2012. With straps set in place on the far side by Brian King, Mike McDowell, owner of San Juan Timberwrights, operates the big forklift.

December 5, 2012. The frame is half way up.

December 5, 2012. The frame is full vertical on its side, stable in position with no support.

December 5, 2012. With one end already sitting on a truck with the center pin in place, Mike McDowell lifts the second end. The forklift would move the frame from side to side, while we pushed the truck along the track. With proper alignment, we dropped the center pin through the center plates on the bolsters.

December 27, 2012. Finally, after delays caused by a snowstorm and the holiday, the gondola frame and trucks are moved from near our summer work shed to Doug Lashley’s hanger at La Plata airport for the winter work sessions. Duane Danielson

2013: Finish Restoration

January 25, 2013. The tops of all the shiplap floor planks obtained their second coat of clear sealer.

January 25, 2013. The plates and large U-bolts for the posts received their red oxide primer. Behind them are the corner brackets (larger for outside and smaller for inside) for the four corners. On the floor behind the stud wall are the steps.

January 30, 2013. The bottoms and outside edges of all the floor planks are painted with a primer tinted with touch of red as a better undercoat for the main color. Duane Danielson

February 1: The bottoms and outside edges of all the floor planks are painted with the reddish top coat. Duane Danielson

February 15: Duane Danielson hammers a brake hanger carrier (J-bolt) in place after Tony Palmer and he had assembled it with the brake hanger.

February 15: Tom Artzberger bends an air line pipe with a hydraulic press.

February: Jerry Hoffer tightens a nut on a stake U-bolt.

February 15: Dennis D’Alessandro drills hole from plate through stake and sill as Jerry checks horizontal alignment of drill bit.

D&RGW Freight Cars

Durango Railroad Historical Society is comprised of a dedicated group of individuals who are united by their interest in narrow gauge railroading and focus on the preservation of southwest Colorado’s railroad history.

The Durango Railroad Historical Society is a non-profit corporation in Colorado and is a public charity under section 501(c)(3) of the Internal Revenue Code.