EMMA SWEENY RESTORATION

In the spring of 2011, when we learned that we would be getting the model from the County of Amador, California, all we had for reference material were VHS copies of the movie and a few still photos. To our great surprise, we were fortunate to learn that Tom Artzberger, Pagosa Springs, Colorado, had a nearly complete set of copies of the full size drawings from Twentieth Century and had made copies in half size. Then, Larry Jensen, author of the book The Movie Railroads, then living in Gunnison, Colorado, donated his nearly full set of full size drawings and copies of a large number of historical photos of Emma Sweeny to us.

Once we had drawings on hand we started making parts (see EMMA SWEENY: NEW PARTS). It took several months to get the necessary paperwork in place with Amador County, then to arrange for transportation. Thus, a few parts were made before Emma Sweeny arrived at Santa Rita Park, Durango on November 4, 2011.

PROGRESS IN REVERSE CHRONOLOGY

25 November 2016. Last spring we were getting a good start on Emma Sweeny early in the season and were sure we would finish and hold a celebration in the fall. By mid summer we had made good progress on four rail cars that had to be completed this fall to meet terms of our State Historical Fund grant. However, the devil is in the details, and the final details took up the remaining time in the fall, causing us to stop work on Emma Sweeny. We will pick up again in the spring and finish for sure in 2017.

We did accomplish several tasks since reporting in our August newsletter. We installed the two full-length rain gutters along the roof edge and the two metal storm windows that swing out from the side of the cab. We installed most of the remaining piping under the cab. We sealed and painted many parts, which certainly brightened up Emma Sweeny. The exceptional new addition was the red and yellow banner for TOMAHAWK & WESTERN and the ship pictures with associated scrollwork on the tender. We had a precise photo of one part of the banner and fuzzy images from a VHS tape of the rest of it. From that we recreated the banner design, with much help from Jon Hammel of Denton Signs, who also made and applied the vinyl material to the tender. Tom Hahl made the two signboards for the sides of the boiler, recreating the edge molding. We will paint, letter them with EMMA SWEENY and mount them in the spring. Denton Signs made stencils for scrollwork on the cab and steam chests, which will be used to paint this artwork in brass in the spring.(Text and Photo: George Niederauer)

December 10, 2015. We ended the season by adding Irish harp pictures the sides of the headlight. The front artwork is repeated on the back. It took five of us on December 3 to lift the heavy headlight and elk horn assembly to the top of the smokebox. We found elk horns that matched those in the movie at the Elk Ranch near Del Norte, Colorado.

Late November 2015. We had new footplates fabricated to replace the ones that were missing. They were needed before we lifted the headlight in place.

December 3, 2105. Panel with “Emma Sweeny” lettering (painted) was installed on the right cab side. Yellow pin stripping (vinyl) was applied in November.

November 23. The new main reservoir (black tank with rivets) is set into its approximate position. Adding piping next spring will determine its permanent position. Earlier in the month we added pin stripping on the sides and rear end and on the cab. The temporary ship picture is an enlargement from a small, poor quality video frame. It will be replaced next spring with an artist’s painting.

August 11, 2015. Air compressor is mounted, but is missing the governor, which connects to the pipe at left side, and the long pipe from the lower cylinder to the back of the engine. Tony Palmer

August 2015. New hinges and a grab bar were added to the repaired smokebox door, now much stronger. Four door lugs are “missing”, so new lugs and spares will be made this winter. Twenty small bolt ends and nuts were added near the edge of the smokebox front.

We replaced many missing or deteriorated wood rivets on the boiler with new plastic rivets (gray).

August 1, 2105. Rivet heads (top half), staybolt heads (bottom half) and inspection plugs nailed and glued to new oak veneer sheet.

July 2015. Coupler and its pocket at the back of the tender. Later, a chain will connect the coupler to the lifting rod.

July 2015. Bolt heads glued to steel sill.

November 13, 2014. The first three riveted DiBond panels are installed on each side of the tender tank. Rivets are not in the holes where artwork on vinyl sheets will be applied.

November 12, 2014. Ron Atkinson (front) and Duane Danielson screw the bottom 12-in x 10-ft panel to the tender tank frame. Aluminum strips (1/4×2-in) give it more thickness. The main panel in 42-in x 10-ft.

November 12, 2014. Jerry Hoffer screws the main panel onto the right side.

November 2015. Tony Palmer and Duane Danielson are gluing rivets to the 3/8” holes drilled in a curve corner panel.

April 25, 2014. The roof lines (white ribs) are fixed the top side rails. The rear wall only has the top rail, to keep the area open for filming.

November 11, 2014. At the end of the painting season, we had fresh paint on virtually the entire engine. Two pipe runs below he running board on the left side still need to get brass paint. The red outer skin of the cab panels are waiting for the ‘Emma Sweeny’ signs to be produced.

September 6, 2014. Most fiberboard have been removed from the tender tank in preparation to add new DiBond sheets.

August 21, 2013. Cab walls, floor, cab brackets, steam dome, and sand box removed for restoration.

August 2013. Note that the bottom plywood flange on the cab bracket is turned up at the inside corner. When restored that corner will be bolted to the steel frame to keep the cab wall from dropping down. The floor has three layers. The bottom planks represent the steel floor. The other two wood layers are typical for cabs of this period.

July 4, 2013. Wheels, rods, cylinders and steam chests restored and painted (except top of right steam chest).

July 3, 2013. Duane Danielson applies whiter primer to cylinder and steam chest edge.

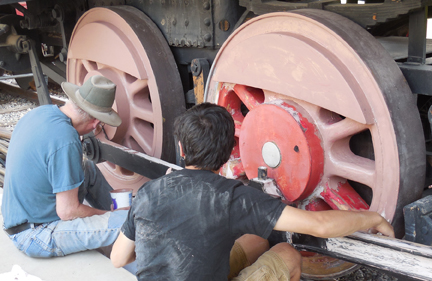

June 29, 2013. Duane Danielson and Bradley Jones priming wheels and rods on the right side.

June 29, 2013. Left side filled and ready for final sanding.

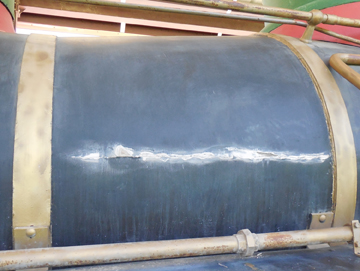

June 8, 2013. Seam in fiberglass boiler sanded and ready for repair.

June 8, 2013. Tony Palmer sands filler on left cylinder head.

June 8, 2013. Duane Danielson reaches in to sand between wheel spokes. Cross head sanded and ready for filler.

June 1, 2013. A view towards the back of the tender tank, after cleaned out and with loose floor boards nailed down. Original curve of tank is shown clearly with plywood pattern on floor, which matches curve of coal bunker collar. (The model has a collar on the interior of the water coal bunker, whereas the real RGS 20 did not – a mistake by the movie studio prop shop, however, to be kept as historical to the model.)

June 1, 2013. An interior view towards the front of the tender tank. Frame structure appears to be in good shape.

June 1, 2013. Plywood boards were screwed down as a crawl way along the boiler interior.

May 28, 2013. Interior of boiler viewed from smokebox doorway. Cleaned and sanitized.

May 28, 2013. DRHS member Evan Kamp, age 11, Tucson, visited and helped to scrape the cab.

May 28,2013. Emile Kamp, age 9, scrapes a steam chest as her father, Aaron, looks on.

May 25, 2013. Work on Emma Sweeny for the 2013 season began with laying down a boardwalk across the tracks made from recycled high side gondola side boards.

July 14 and August 17, 2012. Before and after. After scrubbing and scrapping the front is ready for repairs to begin in July. By mid August the partially restored face was presented at the D&SNG Railfest. The wood draw bar (link and pin coupler) assembly painted brass is in place. Two wood pieces are temporarily placed on the frontmost right wheel. Each stave of the right cylinder was screwed down, and Bondo was added to fill cracks and depressions, then painted brass. The smokebox door is temporarily screwed in place. More work needs to be done to fit it properly and add hinges. Only half the door lugs were ready for display. The temporary number plate is a photo glued to a piece of plywood. The two lantern brackets were stripped of old paint and painted brass. It was a start.

August 14, 2012. Existing parts were falling off the smokebox door, some were missing, and most had gaps between them. Here the door is ready for painting after adding many screws, a few new pieces, and much filler (Bondo, again).

August 10, 2012. Charlie Schumacher made new pieces to replace the missing sections of the front right wheel.

August 6, 2012. The pilot and its brackets are painted red, and the pilot beam black. The saddle for the draw bar is brass colored.

August 5, 2012. Pilot and pilot beam are primed with tinted paint for the alkyd red top coat and white oil-based priomer for the 1-Shot brass paint.

August 4, 2012. Plenty of Bondo was used to fill in cracks and deteriorated surfaces on both the pilot and pilot beam.

August 4, 2012. The staves forming the right cylinder had dried and shrunk, forming cracks and loosening the small nails. Screws would be added at the ends of the staves and in the cracks at the centers to make them solid. The cylinder head was warped, so it was sliced in several pieces and screwed down.

March 2012. Ted Bower of Los Angeles donated the original wood model of the automatic coupler for the tender. It is the only major appliance still remaining intact from the studio prop shop, thanks to it being stored by Ted Bower and his father.

July 28, 2012. The missing end piece and adjacent bottom section were replaced, both glued and screwed into position. The rough top was sanded to smooth out the deteriorated surface somewhat. The three pilot brackets had been held in with short lag bolts, which allowed them to loosen. For a solid structure we used long bolts through to the top of the pilot beam and countersunk to hide the bolt heads.

July 28, 2012. After cleaning up the pilot, we bolted the two outside pilot bars to the top frame member and the middle pilot bar to both the top and bottom frame members. Then, the draw bar bracket had to be installed before the pilot bars on either side of it were attached. Large lag bolts hold the bottom of the outside bars and both ends of other bars in place.

June 9, 2012. Several volunteers joined in the Wash and Scrub day for Emma. Young Joe Weigman (white shirt) brought his friends Ringo Racheff on his left and Cody Racheff on his right. Patty Racheff

June 9, 2012. Joe Weigman really got in the spirit of the work, scrubbinn under the main rod. Patty Racheff

Condition as Received – 2011

The model looks much as it did as the Hooterville Cannonball, except that it is named the Amador Cannonball, has deteriorated and lost many parts. Major changes in converting from Emma Sweeney to Hooterville Cannonball include different stack, headlight, and number plate and the lack of the name boards on the side of the boiler. Much of the paint scheme was changed, too, to match that on Sierra RR 3 for Petticoat Junction.

Based on a preliminary inspection, it appears to need about 53 wood, 27 metal, and 3 plastic component models reconstructed because they are missing or only partly present and much standard piping, along with many fittings and about 25 valves.

All photos by George Niederauer, except those on November 4 (unloading) by Rose Niederauer.

As shown at the front of the engine, the model is built on a solid frame of welded channel steel. All axles are steel pipes that run through short pieces of larger pipe welded in fixed positions on the frame.

Looking back along the engine frame shows that it is well braced with crossed angle irons and steel plates both vertically and horizontally.

Glue joints in the wood smokebox door are coming apart, both hinges are broken at the bolt holes, and several lugs are missing. The headlight and number plate will be replaced with reconstructions of designs for Emma Sweeney.

The open west side of the model really suffered compared to the shady east side. A good example is the cylinder, which will need regluing and epoxy filler, then sanding, to get it back into shape. Where possible, we will restore original wood rather than replace it. Part of the missing snifters (relief valves) on both steam chests will be reconstructed.

The plywood rear face of the firebox will be replace, but the wooden rivet heads can be reused and maybe the staybolt heads. Apparently the model did not include the tricocks – no evidence here or on the drawings. The footplate is missing. Where the turret should be is part of the lubricator – on its side!

The interior of the cab should look virtually as crowded with the same appliances and pipes as on the 315, but most of it is gone. On the left side the red object, where an injector should be, is the triple valve, which should be next to the small driver brake reservoir under the floor on the left side of the cab (green tank in next photo). On the right side only the bases of the brake valves remain, probably because they were attached to pipes (real). Note that some pipes end with flanges attached to the floor.

The cab walls appear to be in decent shape, although the edge of the floor is not structurally sound. The roof has been replaced. The roof joists should be narrow arches, and the half round edging should be a fancier molding. Rain gutters are missing.

The tender frame is constructed similarly to the engine frame. Note the solid wheels with wide iron rims – and no flanges! All brake and springs are for looks only.

An open journal box reveals the wood structure around the pipes for the axle and its sleeve. One of the aluminum covers is missing and will have to be cast.

Pavilion

The locomotive pavilion in Santa Rita Park was originally built by the City for D&RGW 315, but we learned that, as an operating locomotive, it needed to be stored inside. We had a lot of work to do on the 315 after its first winter out in the open, even though protected by a tight fitting canvas tarp. It is now stored in the Silverton Northern engine house.

Once we saw the Amador County Board of Supervisors vote in late April 2011 to release Emma Sweeny to the Society, we starting making plans to prepare for the arrival of the model. In June volunteers assembled the track that was donated by D&SNG and spread the ballast donated by Sandco.

July 7, 2011. The pavilion is ready to accept Emma Sweeny.

We will make other improvements to the pavilion by adding a decorative fence (now in fabrication) around the outside perimeter of the posts, electrical outlets and lighting, and green paint on the fence and posts. Electrical conduit, shown on right foreground post, was installed when the pavilion was built.

Moving Emma Sweeny

Everything finally fell into place on Friday, October 28, 2011, when the trucker called to say he would be in Jackson, California, the next Tuesday. George Niederauer packed up tools, hitched his trailer and left Saturday noon, arriving Jackson late Sunday afternoon. Rod Jensen came over from Ben Lomond, California, Monday morning. After two full days of work Emma was ready for loading.

Amador County staff cleared out trees, branches, and a compost box to provide a direct path in line with the track for the truck. To meet the load width and height limits for a standard move, we removed the headlight; stack; steam dome; cab side grab irons, arm rests, and storm windows; and footboards on the tender sides (added at Sam’s Town). We then removed items that were too loose to travel: pilot, flag stands, smokebox door, rivet heads, tender coupler pocket, journal box covers, etc.

The truck arrived Wednesday morning and was loaded and on the road by mid afternoon. The steep ramp into the parking lot caused the trailer to jerk in going out, shaking the cab so hard we almost lost it right there. At first we were just going to brace it, but upon closer inspection, we discovered that the floor of the cab and the support of the firebox on the frame were badly rotted, no longer structurally sound. So we removed the cab piece by piece and put all in the tender tank. The cab jerk also ripped the front wall away from several pipes; they too were removed and put in the tender.

We arrived in Durango Friday morning, November 4, and unloaded Emma at Santa Rita Park. Good thing. It snowed all day on Saturday.

November 2, 2011. First winched on by cable was the tender, with the rear truck on the front, static part of the trailer.

November 2, 2011. Then, went the engine. With its axles fixed to the frame, only the frontmost and rearmost wheels were taking all the weight.

November 2, 2011. Our big come-along was used to pull the tender and engine sideways to center the wheels on the track, then the trailer. It was J R Sellers (pulling) and his truck that pulled the Skanska trailer, accompanied by Heath Higgins (eyeing the alignment), a Skanska driver.

November 4, 2011. With most of the cab and much of the boiler piping placed inside the tender tank, Emma looked even barer. The truck is backing up to the pavilion in Santa Rita Park.

November 4, 2011. The engine was slowly winched down onto the track. Heath Higgens is checking its progress and alignment to the track. Once on the track, Jim Granflaten pulled it along the track with his pickup and long chains. Heath gave instructions for movement, relayed to Jim by George Niederauer. Back at the engine, Ron Atkinson (blue jacket), Ted Swearingen (gray jacket), Ron Nott, and Chris Killgore (both hidden) push the engine back to the track center as it rolls. It worked sometimes, but mostly we used the come-along.

November 5, 2011, Saturday. After the beautiful, warm weather in Jackson, it was a good thing to have Emma out of there on Wednesday and in the pavilion on Friday. We just missed the snow that hit the Sierra Mountains Thursday and the snow that came down in Durango all day Friday. The pilot, which was transported in the front of the tender, was placed on the rails against the pilot beam. Other than putting some of the parts back on it, we will let it sit over the winter to acclimatize to our dryer climate.

November 17, 2011. A warm fall day allows us to put some parts back on Emma so it has the general shape of a locomotive again. Ron Atkinson (back to camera), Duane Danielson, and George Niederauer (inside smokebox) mount the headlight. Steve Lewis, Durango Herald

November 17, 2011. Lifting the heavy smokestack are Dennis D’Alessandro on top, George Niederauer on the running board, and Tom Atkinson on the ground. On the other side, pulling on the rope, was Ron Atkinson. Steve Lewis, Durango Herald

D&RGW Freight Cars

Durango Railroad Historical Society is comprised of a dedicated group of individuals who are united by their interest in narrow gauge railroading and focus on the preservation of southwest Colorado’s railroad history.

The Durango Railroad Historical Society is a non-profit corporation in Colorado and is a public charity under section 501(c)(3) of the Internal Revenue Code.